HL-1 metal cutting fluid

【Features 】

This product is a new generation of microemulsion cutting fluid designed by our factory and the relevant scientific research departments. The concentrate is yellow to orange transparent solution, after diluted by tap water it turns into translucent liquid (micro emulsion).This product adopts the oily, water-based double lubrication rust, combines all the advantages of the emulsion and the synthesis of liquid, avoid the oil pollution, mouldy and other ills to the emulsion, the service cycle is 3 ~ 5 times of the emulsion regularly. With excellent lubrication, cooling, cleaning and antirust performance. Adding a special additive, to make this product has extraordinary extreme pressure bearing capacity, including the HL - 2 to 5% of the diluent PB value of 882 or higher n (90 KGF) alternative sulfide cutting oil, sulfur, phosphorus type cutting oil or kerosene used for drilling, high-speed fine reaming, band saw cutting, automotive, stretching, screw, nuts, car light, automatic wire, gear processing and deep into the ground for car and harsh working conditions, such difficult cutting material (aluminum alloy, high strength steel, stainless steel, hard alloy, titanium and titanium alloy, etc.) of machining.

【purpose 】

HL series cutting fluid is mainly applied to the lubrication, cooling, cleaning and antirust of the harsh working conditions in processing center such as deep drilling, reaming, high-speed wire, thread fine cars, gear shaper, deep creep feed grinding. HL 1 is mainly used for processing and general high strength steel, ductile iron, stainless steel, hard alloy, etc., the HL - 2 is mainly used for processing of hard cutting material like aluminum alloy, high strength steel, stainless steel, hard alloy, titanium and titanium alloy.

【usage 】

According to the different machining process and material, the product can be made into different concentrations:

1, General condition: 3-5% concentration; For deep slow into cutting or cutting difficult-to-machine materials concentration can increase to 8-15%;

2, For high-speed tapping, band saw cutting, hinge, broaching, nut automatic production machine, deep drilling, using 15-25% concentration;

3, During the harsh processing conditions and machining materials, the concentration can be adjusted to 25-30%.

Above is just for reference, the exact dilution rate under different conditions should be determined after the trial.

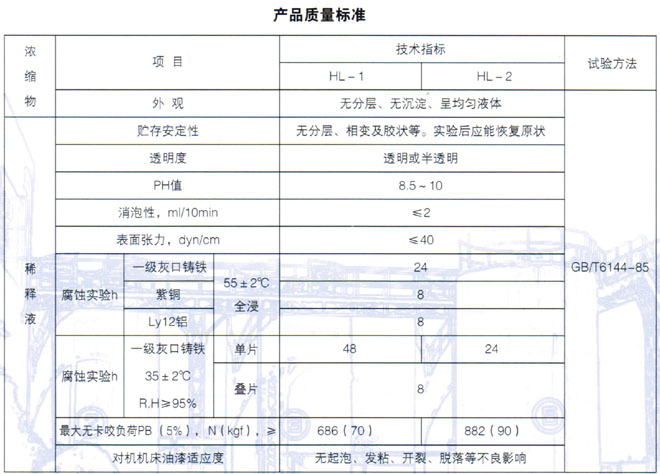

【Quality indicators 】

Products comply with GB/T6144 IV class (multi-effect) quality requirements, but the PB indicator made higher requirements.

【Notes】This product is unfavorable and emulsified oil (liquid) and other brand of cutting oil mix.

【Packaging】200 kg drum packing.

【Storage & Transportation】Handle with care, sealing-up and leak-proof. Store in dry, cool, ventilated storehouse. Storage period is one year.

Previous:SP synthetic Grinding fluid

Next:Stainless steel tube rolling oil series