Steel plate hot rolling oil

Hengfeng HYG Steel plate hot rolling oil

【Features】

1、Using highly refined mineral oil and synthetic oil as base oil to improve the capacity of hot rolling lubrication.

2、Using effective anti-wear and extreme pressure additive to make the oil has better lubrication performance when under the condition of hot rolled high temperature and high pressure.

3、Adding macromolecular compound to make the oil absorbed on the surface of metal roll and steel strip as polar group when under HPHT, enhancing the adhesion of oil film and the lubricity of rolling.

4、During the development of the formula, we give full consideration to the oil-water separation performance and the adsorption capacity of hot rolling oil, so that no additional water treatment equipment is needed. The product is with high flash point and stable thermolysis, so the comburent is non-poisonous, ash content low, smokeless and almost no environmental pollution.

5、Considering to the increasing use of high speed steel rolling technology, we add a special additive to protect the roll.

6、The product is with proper viscosity, easy to transport and spray. And meanwhile it won’t block the nozzle.

7、Suitable for the rolling lubrication technology of all racks.

【Characters】

| Item |

Quality index |

Text method | ||||

|

HYG-1 |

HYG-2 |

HYG-3 |

HYG-4 |

HYG-5 | ||

|

KVIS (40℃) |

108-132 |

54-66 |

58-66 |

40-60 |

55-80 |

GB/T 265 |

|

Density (20℃),g/cm3 |

0.88-0.95 |

GB/T 1884 | ||||

|

Flash point ℃ (opening) |

185 |

180 |

185 |

GB/T 267 | ||

|

Tipping Point ℃ |

-2 |

-15 |

-9 |

-18 |

GB/T 3535 | |

|

Moisture, % |

None |

GB/T 260 | ||||

|

mechanical admixture,% |

0.02 |

0.015 |

GB/T 511 | |||

|

Water-soluble Acids and Alkalis |

None |

GB/T 259 | ||||

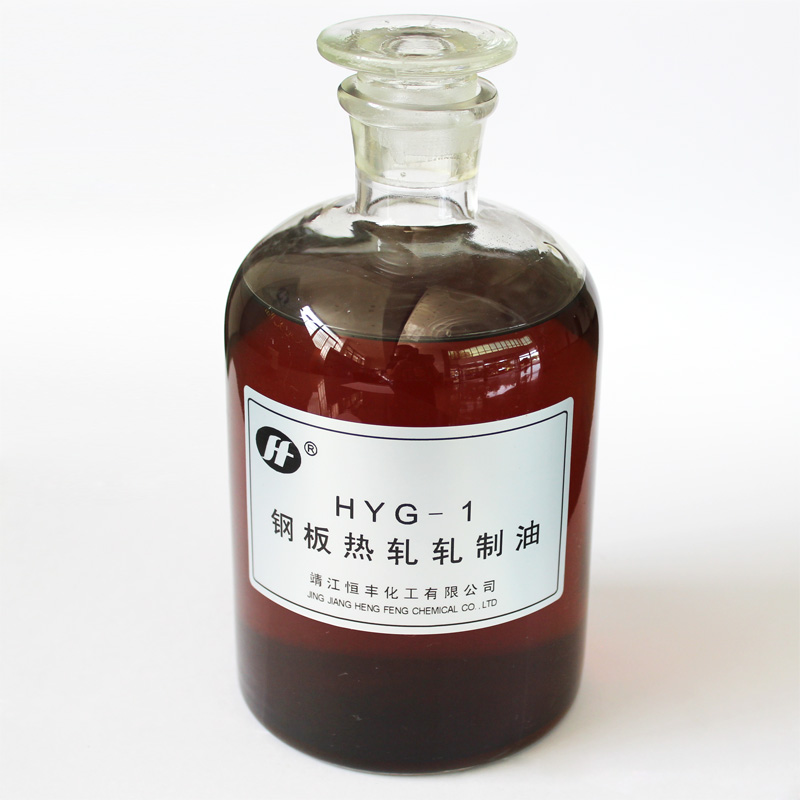

【Performance】

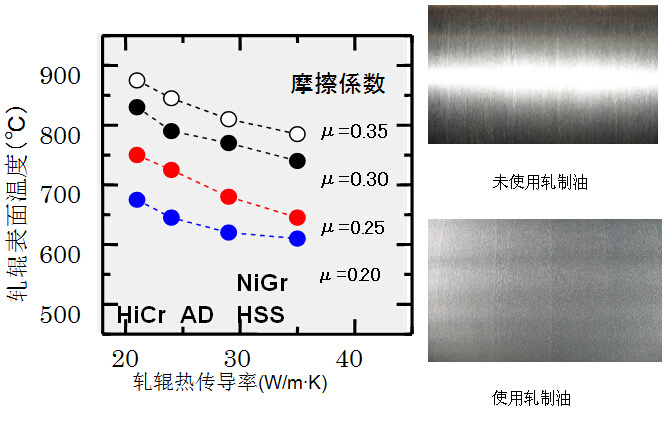

● Reducing the rolling pressure effectively (around 12%) and the load of mill motor (reducing the energy consumption around 8%)

● Reducing the roll consumption (round 30%), to prolong the service life of the roll and increase the mill production.

|

|

| Before | After |

● Reducing the roll changing times and extending the planning rolling mileage of the strip steel (30%-40%)

● Reducing the friction coefficient effectively, protecting the scale on the surface to improve strip surface quality.

【Part of the Achievements】

|

Client Name |

Baosteel |

Baosteel1580 |

Panzhihua Iron and Steel |

Meishan Steel |

Zhujiang Steel |

Tangshan Jane Zhou Steel |

|

Product Type |

HYG-5 |

HYG-3 |

HYG-1 |

HYG-2 |

HYG-3 |

HYG-4 |

|

Mileage Extension |

60% |

40% |

34.5% |

41.7% |

26.5% |

35% |

|

Pressure Drawdown |

15% |

13% |

9.7% |

11.6% |

9.3% |

12% |

|

Pressure Drawdown |

30% |

35% |

27% |

33.7% |

28.9% |

32% |

Main clients

As a professional R&D team, we have been focused on this area from 1996 until now, now we have developed the series from HYG-1 to HYG-4. Besides, we can also design a complete set of hot rolling lubrication process equipment for the customer, we are the TOP Team around China. We sincerely hope to build a long-term relationship with all the clients.

【Package & Storage】

1、Package

Container:170kg Steel Drum

2、Storage

Handle with care, sealing-up and leak-proof.Store in dry, cool, ventilated storehouse.Storage period is one year.

【Use & Care】

The product should not be mixed with other cold rolling oil directly, otherwise the mixed solubility experiments must go first before mixing.

|

|

Previous:High Strength Steel cold rolling oil

Next:Steel Lubricant Series